Roadmap

20

Timeline:

- 2025

- 2024

- 2023

- 2022

- 2021

- 2020

- 2019

- 2018

- 2017

- 2016

Highlights

Stick to technological innovation, Seraphim continues to enhance our capabilities and increase investment in R&D. Through laboratory upgrades, talent team, and cooperative R&D, we keep improving module efficiency and stand at the forefront of the industry.

- 100+ Technology Patents

- 23.5% Module Efficiency

- 7+ Agencies Accredited Lab

R&D Center

A Solar Products R&D Center Accredited by Multiple Agencies

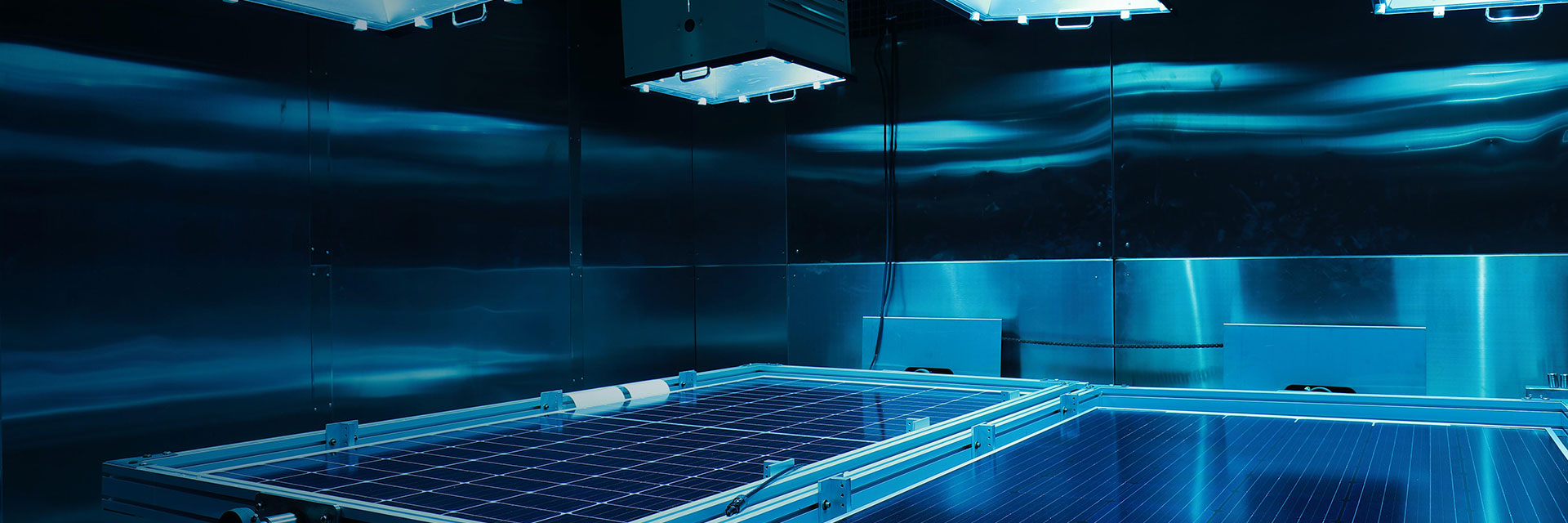

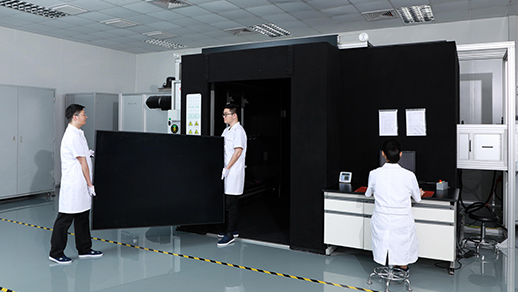

As one of the world's leading manufacturers of photovoltaic products, Seraphim established an in-house R&D center in 2013. The center specializes in R&D and product testing for further development, new materials evaluation, client customization, and periodic sample testing, among other activities, to provide technical support and guarantee product development and quality control.

The laboratory has been recognized as a witness laboratory by CSA, TÜV Rheinland, and DEKRA, while also obtaining accreditations and certifications from CNAS, CTC, TÜV SÜD, CGC, and other globally renowned institutions. These recognitions enable Seraphim to shorten certification periods and accelerate the release of new products under strict reliability control procedures.

Authoritative Third-party Certifications

Key Laboratory Equipment

H.A.L.M Sun Simulator

Seraphim use A+A+A+ rated H.A.L.M solar simulators which have a high-precision manual testing system for IV measurement of solar modules. They are carefully designed to meet Seraphim's R&D and quality control use.

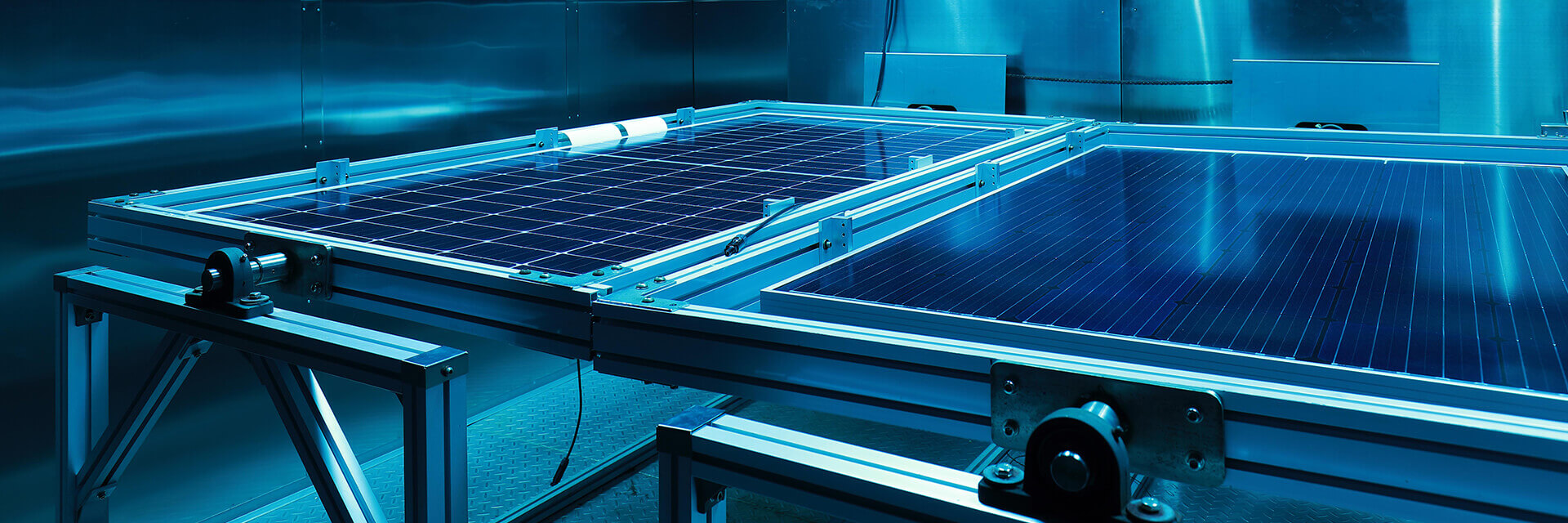

VOTSCH Walk-in Climate Simulation Chambers

VOTSCH customized climate simulation chambers are also embedded in our production lines. These highly precise facilities are made in Germany using eco-friendly materials, which provide detailed testing data for Thermal Cycling tests, Humidity Freeze tests, Damp Heat tests, etc. to facilitate further product upgrades and reliability improvements.

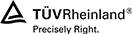

ATLAS Light Source

The light source equipment is from Atlas, which is the selected manufacturer of IEC calibration. The device is equipped with a special 2000W metal halide lamp, which provides highly intensive UV-B and UV-A sections of the UV band spectrum.

A Tour of Our R&D Lab