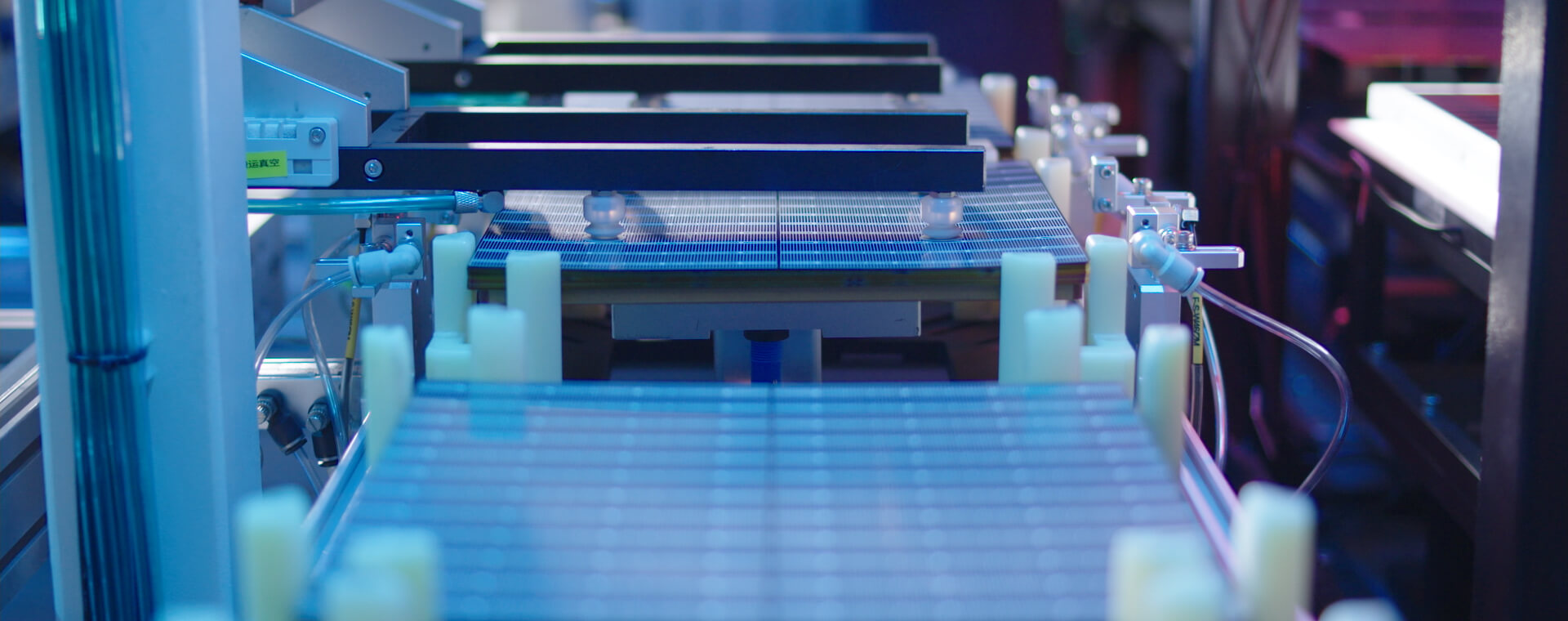

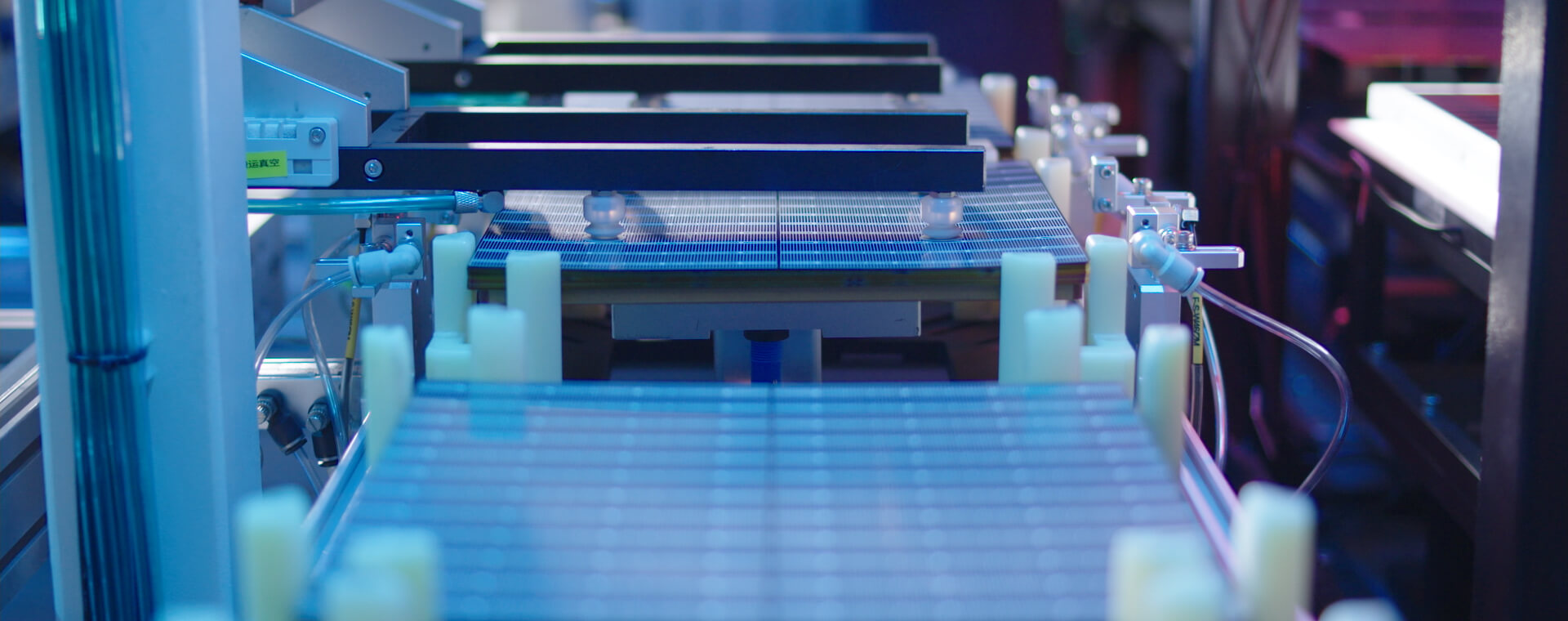

AI-empowered Highly Flexible Modular Fully Automatic Production Line

Highly interconnected modular dedicated production lines and automated production lines combined with self-developed intelligent quality management systemsensure the high quality of Seraphim products

100 +

Patents on Production Process Optimization

15 %

Lower Production Cost

35 %

Higher Production Efficiency

15 %

Higher Equipment Effectiveness

Real-time Monitoring System

Starting from the first step of production, the ERP system assigns a unique barcode to each module. Information such as raw material suppliers, operators of each process, results of each online inspection, and production date can all be viewed online through the ERP system. The data is stored on our servers for retracing all details, and it is available to clients as well. Thanks to this, Seraphim realized full-cycle monitoring of products. This huge database provides data support for us to standardize product manufacturing and process improvements further, as well as significantly improve the yield rate.