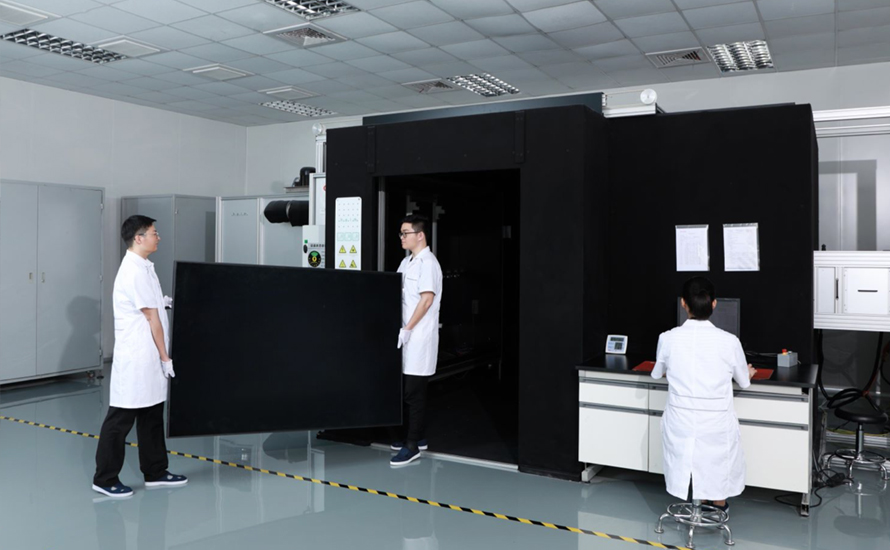

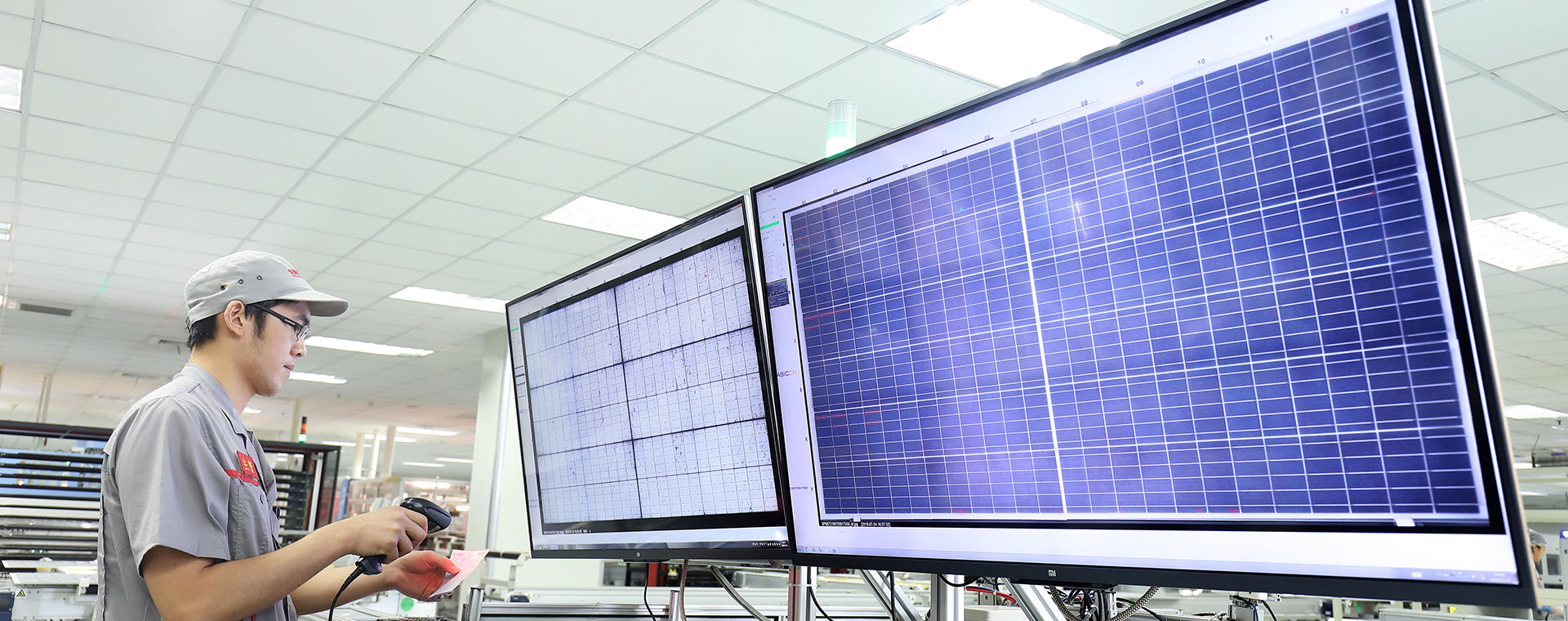

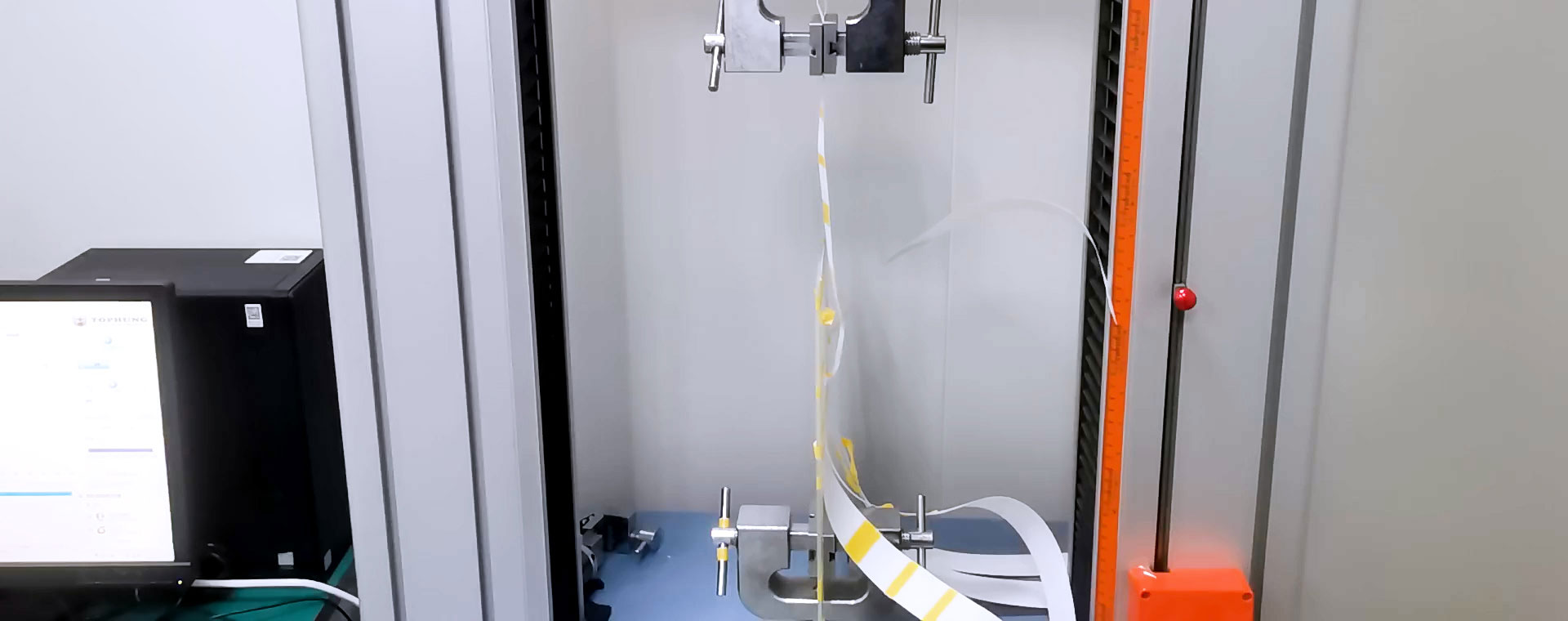

Coordinated Quality Control System

QC Key Points

Third-party Certification

Quality is Seraphim's core competitiveness. Starting from the initial stages of production, we rigorously control every step and hold ourselves and our products to strict standards. We take pride in the quality and reliable performance of each one of our modules, even in the most extreme conditions.

After an on-site inspection and comprehensive evaluation by the expert group of Det Norske Veritas (DNV.GL), Seraphim successfully passed the three system certifications, including ISO9001: 2015 Quality Management System Certification, ISO14001: 2015 Environmental Management System Certification, and ISO45001: 2018 Occupational Health and Safety Management System Certification.

In addition, Seraphim also applied the "GB/T 19580-2012 Criteria for Performance Excellence". It is not only applicable to the selection of the National Quality Awards, but also puts forward requirements for enterprise organizers, customers, employees, suppliers, partners, etc., to guide enterprises to self-learning, pursue outstanding performance, improve product, service and operation quality, and enhance competitive advantage.